TRUE IMAGE TECHNOLOGY for reliable position feedback without purge air

Discover intelligent and innovative solutions for machine tools and production automation: “Empower Manufacturing” is this year’s motto for HEIDENHAIN and its brands AMO, ETEL, NUMERIK JENA, and RSF at the EMO 2025 trade show in Hannover, Germany. Showcasing exciting new solutions and product enhancements, HEIDENHAIN and its brands are empowering users and machine manufacturers to produce with even greater efficiency and agility.

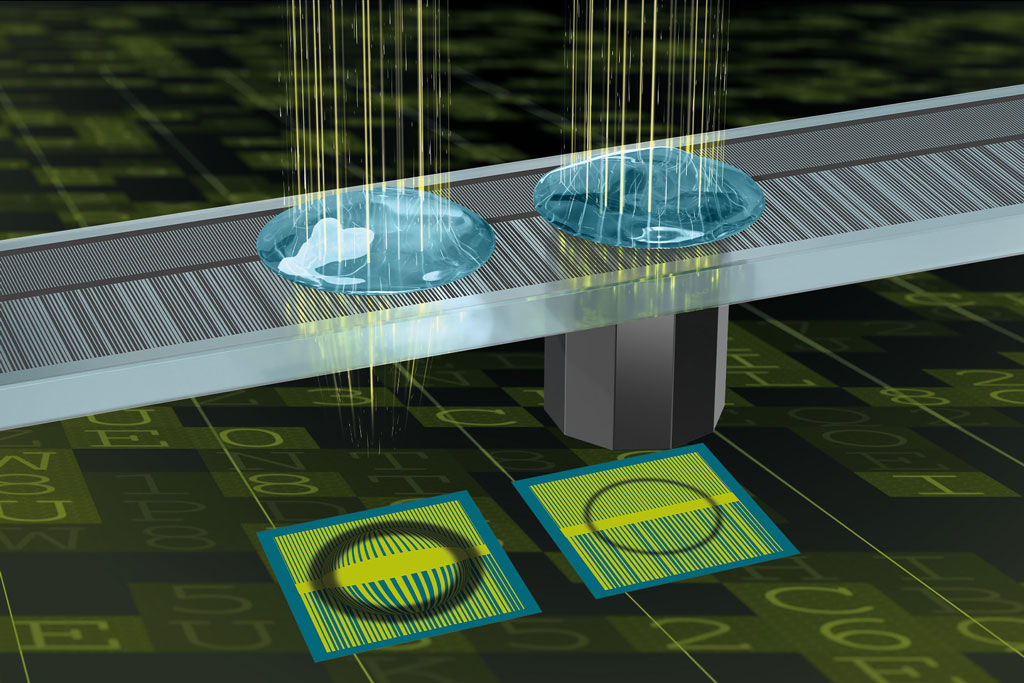

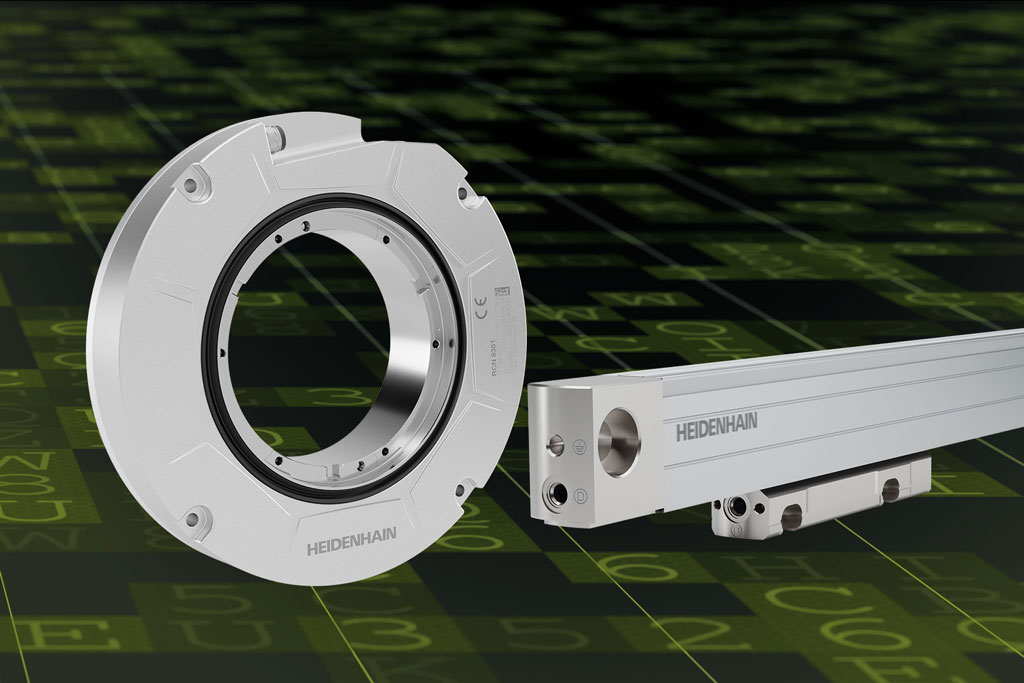

The use of coolant during machining leads to condensation and liquid contamination in the machine tool. But the sealed series 6 LC linear encoders and the series 1 RCN angle encoders with integral bearing from HEIDENHAIN deliver clear scale readings despite contamination. The innovative TRUE IMAGE TECHNOLOGY ensures this.

A special light guiding element fully eliminates the typical optical distortion of a graduation that occurs when, for example, there are droplets on the scale. An unobstructed image of the graduation lines arrives at the scanning head even if there is liquid contamination. The purge-air system of a machine can be greatly simplified, the carbon footprint of the encoders is reduced by up to 99%, and the overall system costs are lowered significantly. And by reducing the number of components in the purge-air system, the TRUE IMAGE TECHNOLOGY also makes quicker installation of the encoders possible.

Thanks to the contamination-resistant optics of these encoders, machine tools are able to stay productive for longer periods, and not needing purge air increases machine availability. For example, the LC 6 series of linear encoders has proven itself in tool-grinding machines for several years now. The encoders don't require any purge air despite being in production environments with much liquid contamination.