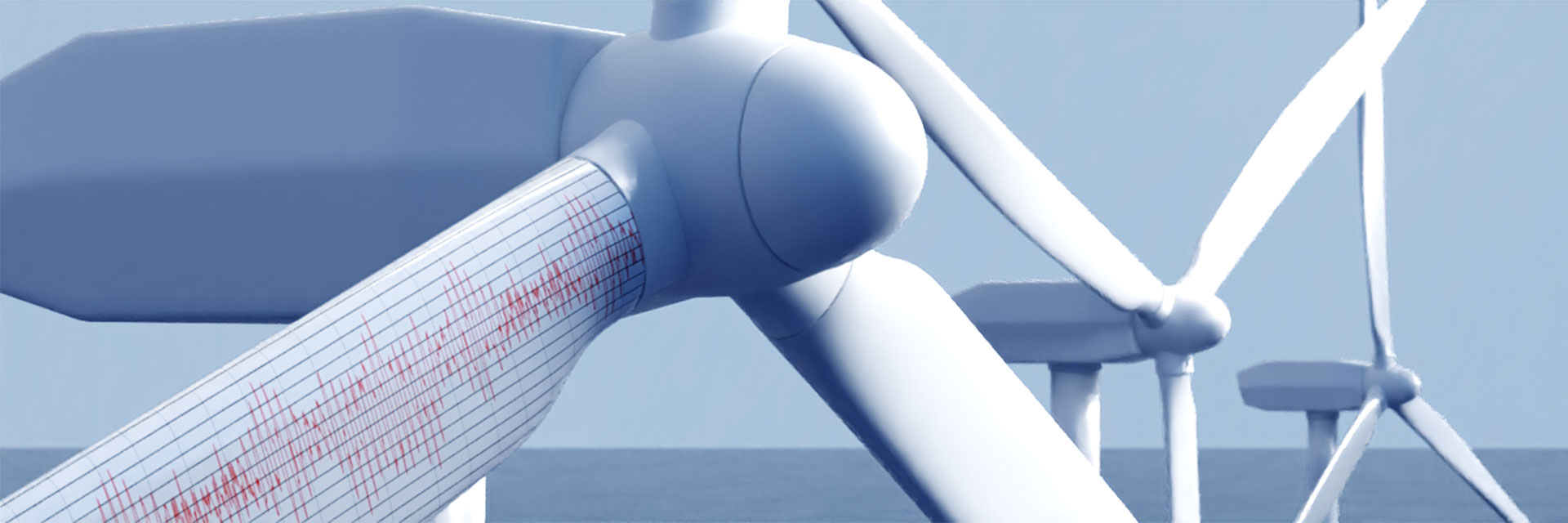

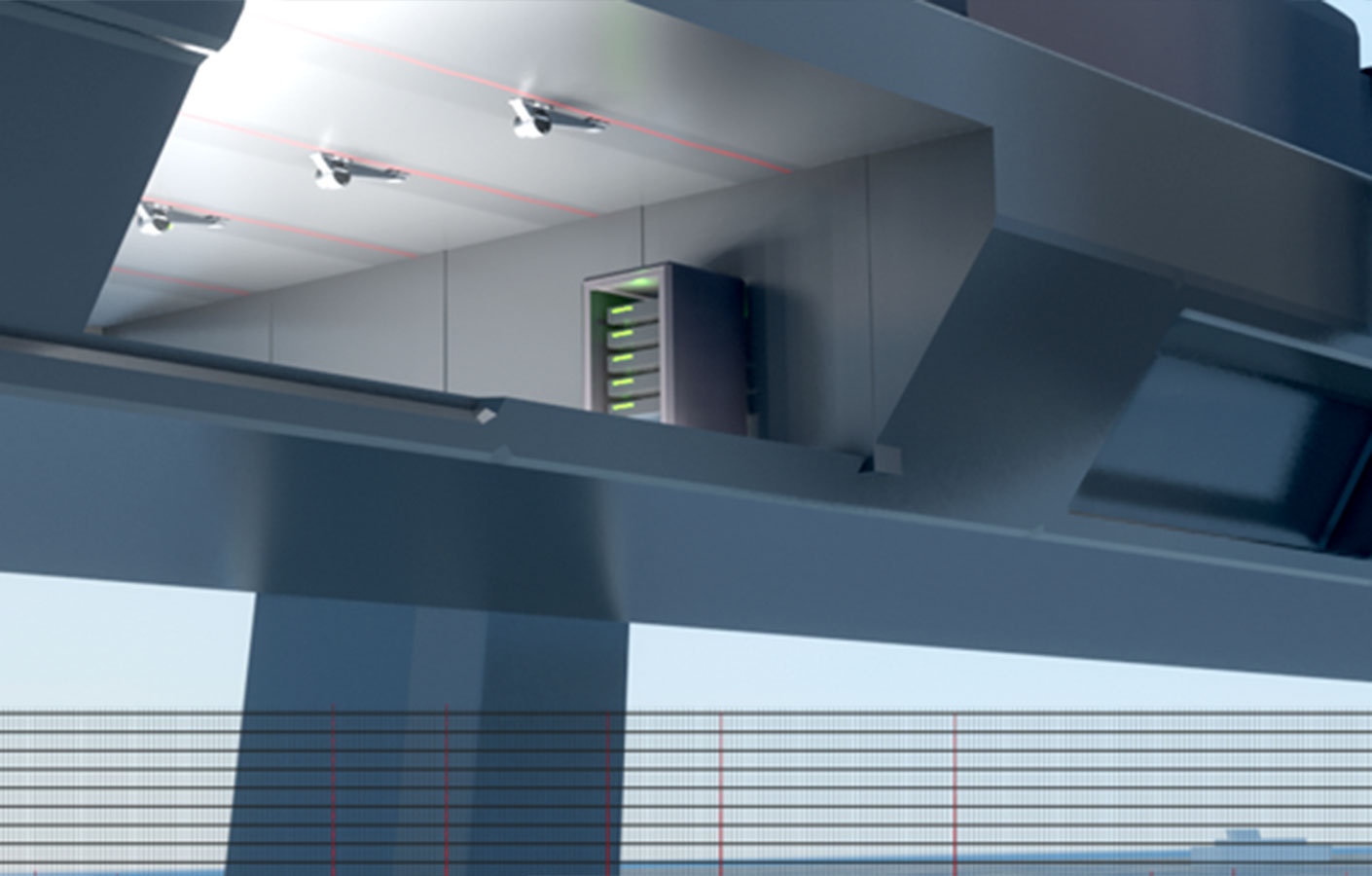

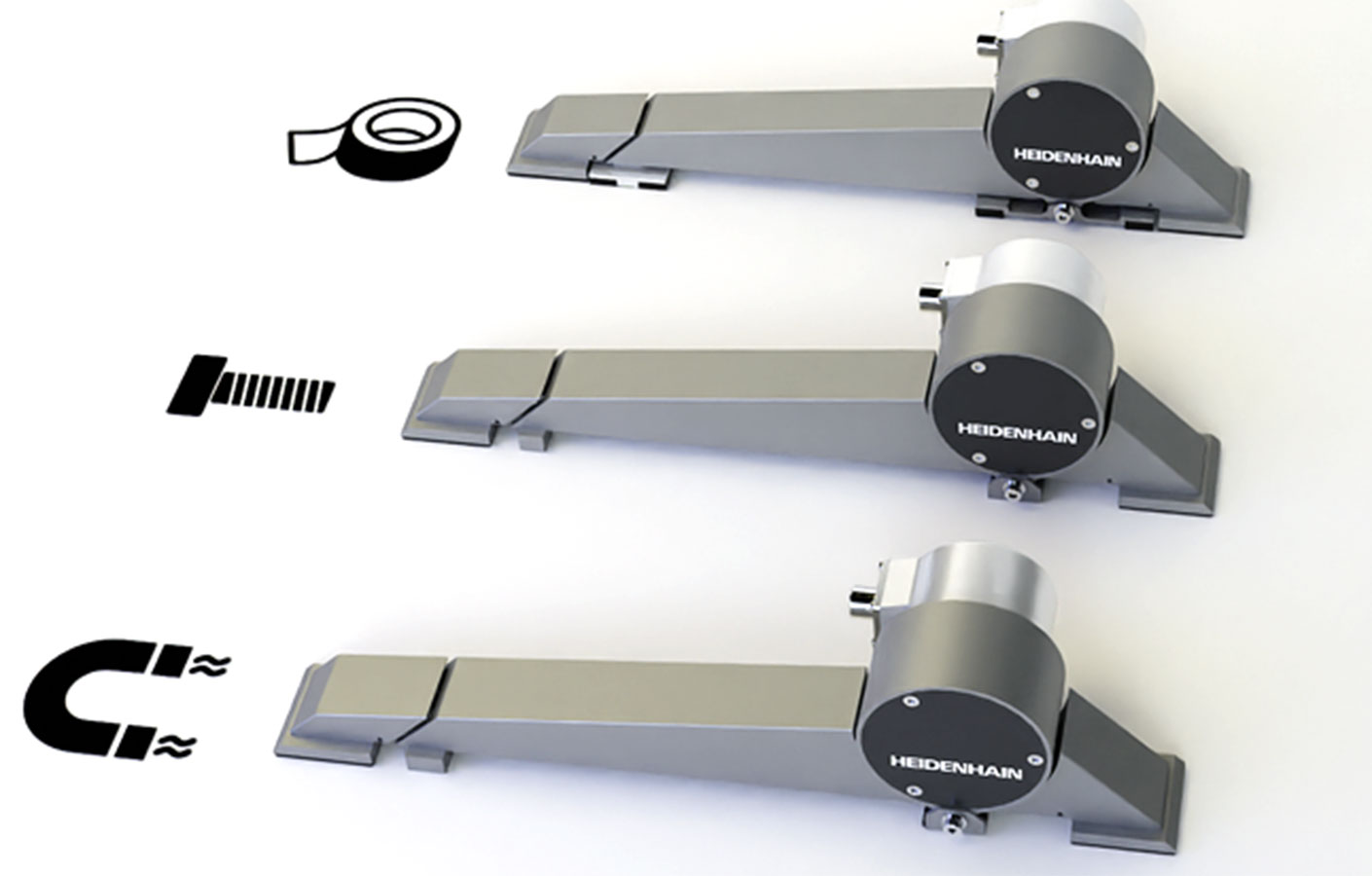

Structural Health Monitoring

Civil and industrial structures must withstand a wide variety of loads from environmental factors and design conditions. Robust, high-accuracy

ESR sensors from HEIDENHAIN and LEINE LINDE measure structural strain and vibration for comprehensive monitoring. They provide solid data for optimizing the operation and maintenance of cranes, bridges, wind turbines, industrial mixers, high-load buildings and automated warehouse systems.