HEIDENHAIN at EMO 2023:

reducing costs and carbon footprints

Solutions that make machine tools more resource- and cost-efficient by reducing machining times, idle times and downtime are certainly the most effective measures for reduced energy demands on the shop floor. That's why, at EMO 2023, HEIDENHAIN is focusing on reducing carbon footprints while achieving even higher process reliability.

Today's manufacturing challenges include better machine utilization, achieving higher quality and producing more quickly while consuming fewer resources. To reach these goals, machinists expect their machines to remove more material in less time and with a smaller carbon footprint but still achieve perfect results starting from the very first part. Intelligent solutions from HEIDENHAIN open up new horizons for maximum performance, process reliability and cost efficiency.

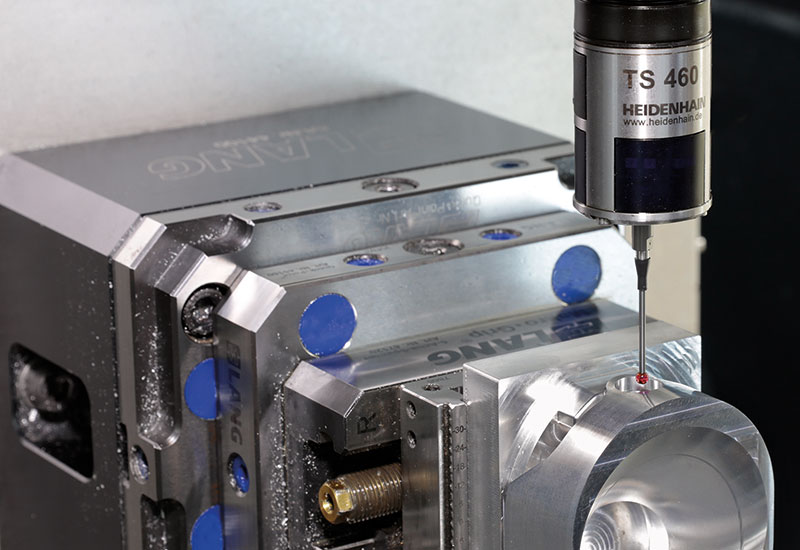

TS 460 and TS 760 from HEIDENHAIN: gain productive time

Faster in-process setup and probing are made possible by the TS 460 workpiece touch probe from HEIDENHAIN, featuring high measurement feed rates of up to 3000 mm/min. The time saved during probing, which can be as great as 30%, then becomes available to machinists as valuable productive time on the shop floor. The integrated flusher/blower of the TS 460 ensures high measurement accuracy by cleaning any chips from the probed surface that would otherwise falsify results. The touch probe can also be equipped with an effective anti-collision buffer that not only prevents expensive damage but also decouples the touch probe thermally. The TS 760 touch probe from HEIDENHAIN enables workpiece measurement with high 3D accuracy and low probing forces. This makes it ideal for precision parts in moldmaking and for highly sensitive workpieces. The measurement feed rates of up to 1000 mm/min ensure a high level of performance.

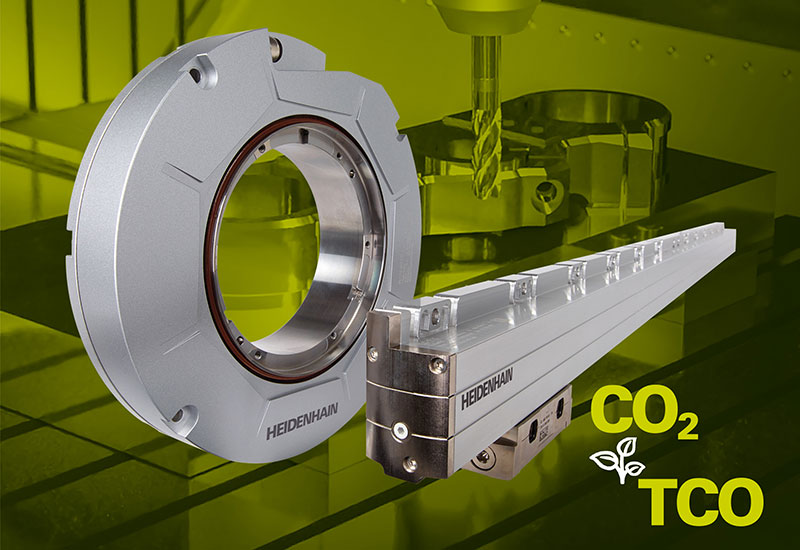

LC and RCN encoders from HEIDENHAIN: 99% less CO2

For the machine component market, HEIDENHAIN is presenting the LC linear encoders and RCN angle encoders with optimized optics for crystal-clear sensing, even in the presence of liquid contamination and condensation. In many cases the encoders operate reliably without purged air. This simplifies sealing-air needs, letting you enjoy the benefits of closed-loop position measurement at significantly lower system costs. Also, omitting the sealing air reduces the machine's carbon footprint by up to 99%. The HEIDENHAIN website features a special online tool for calculating the specific potential savings: www.heidenhain.com/co2footprint

The LB 383C from HEIDENHAIN: the measuring scale for long axes

The LB 383C sealed linear encoder from HEIDENHAIN is the new specialist for position measurement on machines with long axes of up to 72 m. Thanks to its robust scanning unit, the new LB 383C is highly immune to contamination. It also features high rigidity in the direction of measurement. This increases process reliability and allows for higher control parameters for greater machine performance. The LB 383C also saves money thanks to profiles adapted to those of the LC 200 linear encoders: this not only reduces the amount of stock needed, but also eliminates the need for special purged air connectors

Uli Poestgens

Marketing Communications

+49 8669 31-3952

presse@heidenhain.de